Stability

Continuously provides a water recovery rate of over 90%, offering higher system reliability, faster delivery speed, more professional services, and technical support.

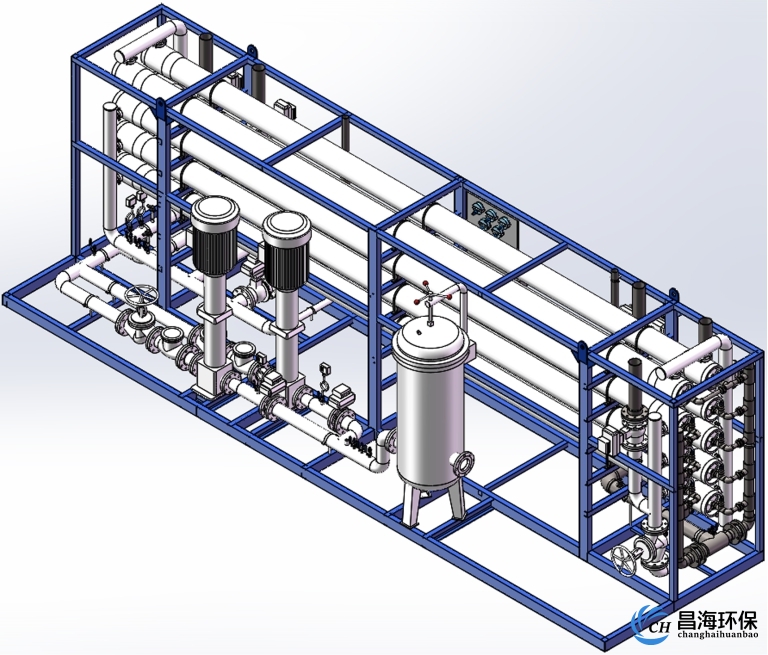

Reverse osmosis equipment is a technologically mature pure water treatment technology.

It enhances the purity of water by removing impurities and salts through reverse osmosis elements;

The water quality produced by reverse osmosis equipment is stable and can meet the water requirements of various industries.

Reverse osmosis equipment processes raw water through fine filters, granular activated carbon filters, and compressed activated carbon filters, then pressurizes it using a pump. Utilizing a reverse osmosis membrane with a pore size of 1/10000μm, it converts high-concentration water into low-concentration water, while isolating industrial pollutants, heavy metals, bacteria, viruses, and other impurities that are extensively mixed in water. This meets the water quality requirements needed for industrial production. Since the purity of water produced by RO technology is the highest among all water production technologies currently available to humans, with a cleanliness that is almost 100%, this type of water production machine is referred to as reverse osmosis equipment.

*Different process flows are selected to fully ensure water standards and meet actual production needs.

Changhai Environmental Protection has extensive experience in the design and manufacturing of Reverse Osmosis (RO) systems, which are used for desalination of seawater and many other water purification processes.

RO utilizes cross-flow membrane separation technology to remove large molecules and dissolved substances from solvents (usually water). The substances retained in the separation effluent can be organic or inorganic and typically have dimensions of several angstroms. Separation depends on molecular weight, geometry, load, and other factors.

Some applications of RO include:

There are various types of reverse osmosis membranes on the market, including high retention, low pressure, anti-fouling, and heat-sterilizable membranes. Choosing the correct type and quantity of membrane for a project depends on the quality of the feed water and the desired quality of the product water (permeate).

Due to variations in water quality, it is often necessary to condition the feed water to maximize the life of the membrane and to avoid fouling, scaling, or degradation.

Continuously provides a water recovery rate of over 90%, offering higher system reliability, faster delivery speed, more professional services, and technical support.

Considers from both economic and technical perspectives for customers, reducing process steps by up to 30%, and significantly increasing pure water production.

Core membrane elements use imported (DOW/SUEZ/HYDRANAUTICS) reverse osmosis membrane elements, ensuring high salt rejection rate, quality assurance, and reducing operating costs.

Committed to fulfilling after-sales service promises, whether it is solutions, equipment installation, remote diagnostics, equipment spare parts, or equipment maintenance, support will be provided around customer needs.

Electronics and Semiconductor Industry

Semiconductor-grade ultra-pure water for semiconductor chips, packaging, integrated circuits, LCD panels, conductive glass, cathode ray tubes, and PCB industries.

Deionized water for electroplating processes, and pure water for surface coating and cleaning.

Pure water for lithium battery production, monocrystalline silicon, semiconductor wafer cutting and manufacturing, glass edge grinding, cleaning, and coating processes.

Food-grade purified water for beverage, beer, dairy food processing, and beverage production.

Process water for chemical reaction cooling, chemical reagents, fertilizers, fine chemicals, and cosmetic production.

Home/Commercial Water Purification Equipment

Provides high-performance home/commercial reverse osmosis water purification equipment to meet the demand for healthy drinking.

昌海环保依靠多年的技术经验积累,在用于食品加工领域的水处理设备已非常成熟。食品业用超纯水设备采用预处理、反渗透技术、超纯化处理以及后级处理等方法,将水中的细菌、杂质完全去除,又将水中不离解的胶体物质、气体及有机物均去除至很低程度。

二级反渗透设备是一种大型的水处理设备。二级反渗透设备又称为双级反渗透设备。二级反渗透设备产生的水是经由将原水加压送至预处理系统进行粗过滤,再进入过滤器过滤后,通过一级高压泵加压送至一级反渗透系统,然后再由2级高压泵加压送至2级反渗透系统,生产出高品质生产工艺需求用水。

本页面旨在探讨纳滤技术在处理难降解高COD废水中的应用,以及选择合适的预处理技术的重要性。内容涵盖高级氧化技术如臭氧催化氧化和芬顿法的使用,以及它们在实际应用中可能遇到的挑战。同时,本页面也会提供一些建议,以帮助读者更好地理解和应用这些技术。

纳滤膜能截留纳米级(0.001微米)的物质。纳滤膜的操作区间介于超滤和反渗透之间,其截留有机物的分子量约为200-800MW左右,截留溶解盐类的能力为20%-98%之间,对可溶性单价离子的去除率低于高价离子,纳滤一般用于去除地表水中的有机物和色素、地下水中的硬度及镭,且部分去除溶解盐,在食品和医药生产中有用物质的提取、浓缩。

NF270-440纳滤膜元件处理地表水和地下水的公共设备经理和运行人员,寻求能高度脱除总有机碳(TOC)和三卤甲烷(THM)前体同时允许硬度中等透过,其它盐分中等到高等透过的产品。

东莞市昌海环保是一家专业生产销售RO反渗透设备的厂家企业,昌海环保的RO反渗透纯水设备根据不同的源水水质采用不同的工艺。一般自来水经一级反渗透系统处理后,产水电导率<10-20μS/cm,经二级反渗透系统后产水电导率<5μS/cm甚至更低,在反渗透系统后辅以离子交换设备或EDI设备可以制备超纯水,使电阻率高达18兆欧姆.厘米。 反渗透膜老化或受污染后,产水质量会下降。

工业反渗透超纯水设备是采用目前国际上较为先进的反渗透除盐技术和EDI技术。 工业反渗透超纯水设备具有能长期不间断工作,自动运行无需专人看管,操作简单,且水质长期稳定,无污染物排放,制取纯水成本低廉等优点。

纳滤反渗透膜组件排列方式分析:一个标准的工业RO或NF装置如图所示,膜元件串联排列在压力容器内,几个压力容器并联排列成一段、两段或更多段,构成特定的一个系列,第二段通常用来处理一段的浓水,以提高回收率。

Customize the equipment you need for water purification, optimize performance, and save costs.